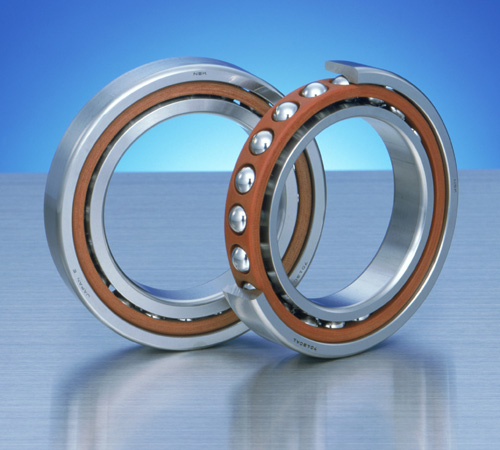

Single row radial thrust ball bearing

The bearings with this structure of can bear radial load and axial load in one direction. The ball has contact angle of 15 degrees, 25 degrees, 30 degrees or 40 degrees with the inner ring and the outer ring. The larger the contact angle is, the greater the bearing capacity of axial load is. The smaller the contact angle is, the more favorable high speed rotation is.

Usually fold two bearings and adjust the internal clearance before use.

Generally use the steel plate stamping holder. However, the high precision bearings with the contact angle of below 30 degrees mainly use polyamide forming holder.

Double row radial thrust ball bearing

Double row radial thrust ball bearings are the structure that 2 single row radial thrust ball bearings are same on the back side of the outer ring and combines the inner ring and the outer ring into each one . Therefore, the bearings of structure have two directions thrust load capacity.

Bearing ("Bearing", the Japanese call "shaft") is a component that is used to fix and reduce the friction coefficient during the process of mechanical transmission. It can also be said to be the machine parts which are used to reduce the friction coefficient during power transmission and keep the machine shaft center position fixed when the relative movement occurs on the other parts on the shaft with each other. Bearings are one of the most important share parts in modern mechanical equipment. Its main function is to support the mechanical rotating body in order to reduce the mechanical load friction coefficient during the transmission process. According to the different friction properties of the components, bearings can be divided into two types of rolling bearings and sliding bearings.

It should be supported in terms of its role , that is,the load axis in the literal interpretation. But this is one part of its role and its essence is to support the radial load. It also can be understood that it is used to fix the shaft. It is the fixed axis that only enables it to rotate while controlling its axial and radial movement. The consequences of motor without bearing are not completely to work. Because the shaft may move in any direction and shaft can only rotate when motor works.Speaking theoretically this could not achieve the transmission effect, not only that, the bearing will also affect the transmission.In order to reduce this effect, good lubrication must achieve in the bearings of high speed shaft.Some bearings themselves have some lubrication, which called preliminary lubricated bearings.And most of the bearings must have lubricating oil to load when running at high speed. Because friction will not only increase the energy consumption, more terribly is very easy to damage the bearing. The idea of turning sliding friction into rolling friction is one-sided because there is something called a sliding bearing.

Valve mp3 shaft mechanical parts ball gasket motor gear wheel fasteners guide wheel tire grinding wheel engine reducer standard parts worm transmission enameled wire machine tool synchronous belt read mechanical drawing gear base bearing with oil ceramic bearing single directional bearing self extinguishing tube DMD yellow wax tube AAA bearing single suction valve